AVEVA™ Edge

AVEVA™ Edge

Develop your project once → Deploy and run it anywhere

AVEVA Edge™ is a proven solution that allows end users, systems builders, and OEMs to innovate with new HMI solutions at low-cost, and convert legacy third-party applications with one click.

- AVEVA Edge provides hundreds of communication drivers, language switching, recipe management, advanced graphics, built-in web and mobile access, reporting, scripting, data logging, and more.

- AVEVA Edge runs the same developed application on Linux/embedded and Windows operating systems.

- AVEVA Edge can scale from your smallest IoT project to larger SCADA applications and easily import and convert legacy FactoryTalk™, PanelBuilder32™, and PanelMate™ applications.

- AVEVA Edge integrates with AVEVA Historian, AVEVA Insight, and AVEVA System Platform and shares the same Industrial Graphics technology as InTouch and Citect. Develop once and reuse across every AVEVA platform across your enterprise.

Welcome InduSoft Users!

InduSoft Web Studio is now AVEVA™ Edge, and you’ll now receive all technical support, licensing, and training from Wonderware North. Click the button below for more information.

Success Story

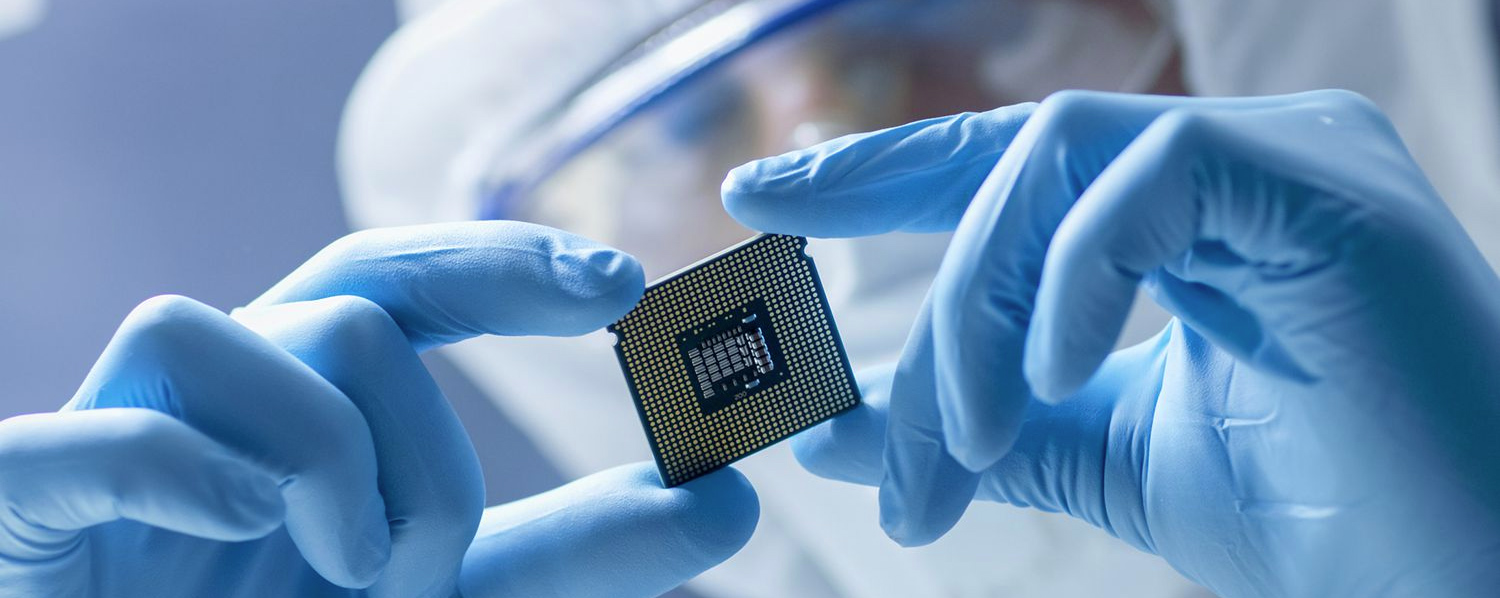

To meet increasing market demands, a bulk semiconductor crystal manufacturer required a state-of-the-art manufacturing facility that would allow increased production while ensuring the necessary quality and performance required by their customers. This facility would rely on a shop floor system built on AVEVA software that provided end-to-end traceability and genealogy of the entire manufacturing process along with instant visibility into that process from any location.

This combination of groundbreaking manufacturing technology and an AVEVA shop floor system (including AVEVA System Platform, InTouch, Edge and MES) implemented by Wonderware North allowed production goals to be met and provided the basis for attaining ISO 9000 certification for the facility.

Product: Bulk Crystals for Semiconductors

Industry: Semiconductor

Location: United States

Software: AVEVA Edge, AVEVA Historian, AVEVA System Platform, AVEVA MES Quality

Project Goals:

- Build ISO 9000 certified state-of-the-art production facility

- Meet expanding production demands

- Ensure product quality while meeting increasing production targets

- One year timeframe get plant online

Challenges:

- Multiple different processes required to be integrated together in an expandable and supportable system

- End to End genealogy required for entire production process to deliver on customer quality assurance requirements

- Implementation window

Results:

- Fully functioning ISO 9000 Facility completed on-time

- 250 individual furnaces monitored by AVEVA Edge as the local operator interface

- AVEVA Edge provides Historian Integration, video integration and web interfaces for remote monitoring of all 250 furnaces.

- Centralized Control System built on AVEVA System Platform with integration to AVEVA Edge on furnaces

- AVEVA MES for production tracking and quality with web-based clients

- The capture, storage, and reporting of critical process data and complete genealogy for each serialized wafer

- Data captured includes operations, such as Slicing and Grinding which are critical to the finished wafer’s properties and must be tracked as part of the overall production process

Certified AVEVA Edge Training

AVEVA Edge online training is a 4-day, instructor-led course designed to provide a fundamental understanding of the features and functionality of the AVEVA Edge software. Students will learn to connect to devices and how to develop, modify, and troubleshoot AVEVA Edge applications. (AVEVA Edge now encompasses InduSoft Web Studio)